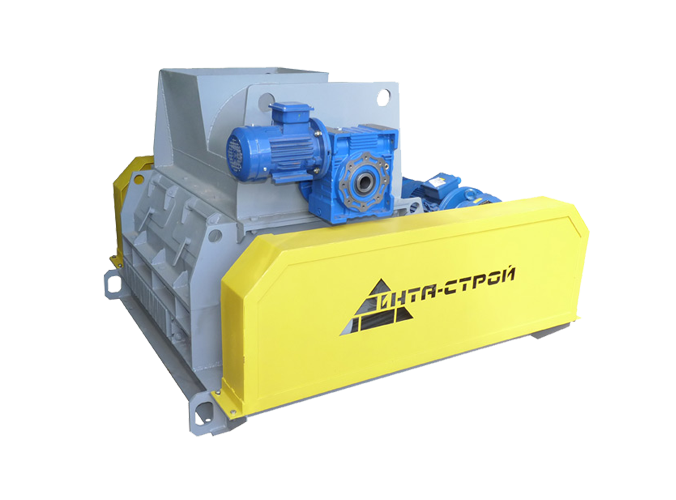

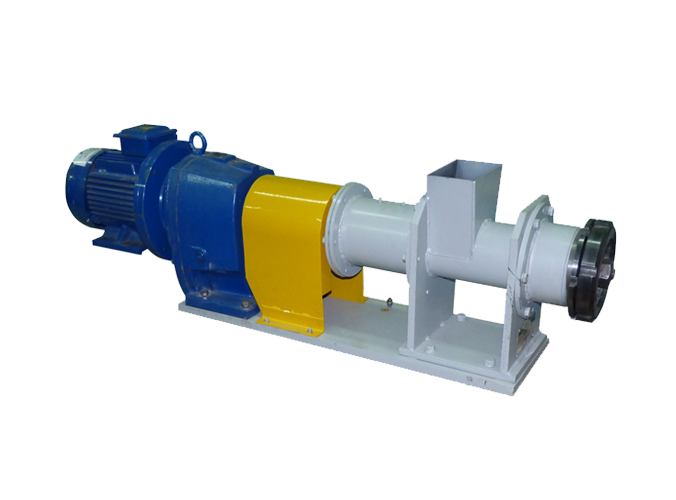

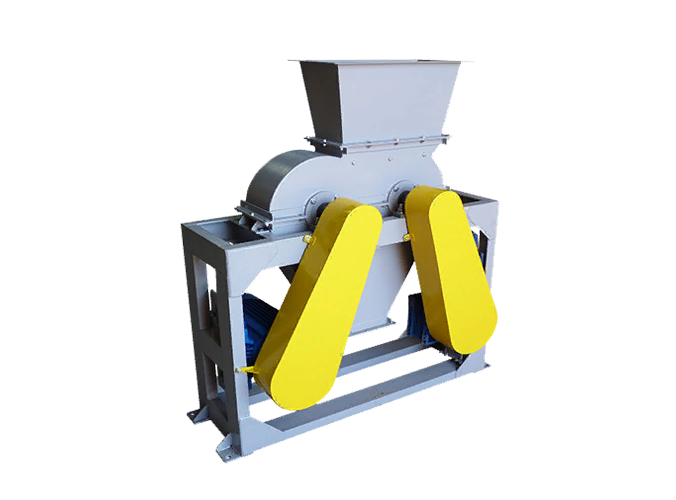

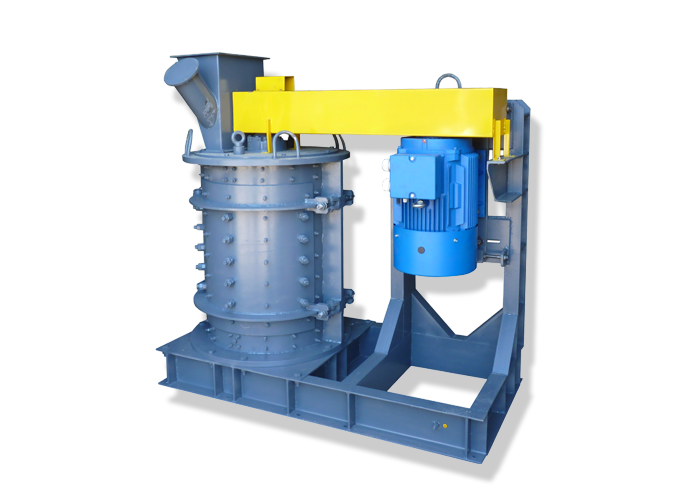

Design and operation principle

The body frame of the hammermill is equipped with hinged doors for easy replacement of wear parts. The hosing area of the frame is protected by segmental lining. The vertical type rotor is installed at bearing supports of the mill body frame. The low bearing support is taken out of the crushing area to improve operating factors of the bearing. Breaker bars are fixed with hinges. The reverse rotor rotation increases the operational life of the breaker bars.

Material for crushing is fed by transporting device through a charging hopper. Crushing is achieved by application of impact action of the breaker bars on raw material.

“Inta-Stroy” produces four types of hammermills in accordance to fineness ratio:

Each type of hammermill is characterized by definite number of breaker bars, rotor speed and opportunity to control the degree of grinding by changing the rotor speed. It is necessary to install a frequency drive.

The main advantages

high fineness ratio (i = 8… 128)

increased operational life of breaking bars

easy replacement of wear parts (breaking bars, lining)

protection of bearing system from dust, occurring during crushing

optional installation of frequency drive (at the customer’s request)

Order

Order

Technical characteristics

|

Capacity, up to t/h

|

2,5

|

5

|

10

|

20

|

40

|

60

|

80

|

100

|

|

Drive power, kW

|

11

|

15

|

22

|

45

|

75

|

90

|

150

|

160

|

|

Max. Size of feed lump, mm

|

70

|

90

|

120

|

150

|

200

|

250

|

300

|

350

|

|

Fineness ratio

|

coarse

|

8...16

|

|

medium

|

16...32

|

|

fine

|

32...64

|

|

subsieve

|

64...128

|

|

Number of breaker bars

|

coarse

|

3

|

|

medium

|

4

|

|

fine

|

5

|

|

subsieve

|

6

|

|

Impact velocity, m/s

|

coarse

|

25...30

|

|

medium

|

30...40

|

|

fine

|

40...50

|

|

subsieve

|

50...70

|

|

Nominal rotor diameter, mm

|

320

|

400

|

500

|

800

|

1100

|

1400

|

1600

|

1800

|

|

Rotor speed, r/min

|

coarse

|

1500

|

1200

|

960

|

650

|

500

|

400

|

350

|

300

|

|

medium

|

2100

|

1650

|

1350

|

850

|

620

|

480

|

420

|

380

|

|

fine

|

2700

|

2150

|

1750

|

1080

|

780

|

620

|

540

|

480

|

|

subsieve

|

3600

|

2900

|

2300

|

1450

|

1050

|

820

|

720

|

630

|

STILL HAVE QUESTIONS?

Write your questions in the application, and we will be happy to advise you. You will receive a professional answer to your questions.

Feedback

Feedback

Order

Order