Waste wood.

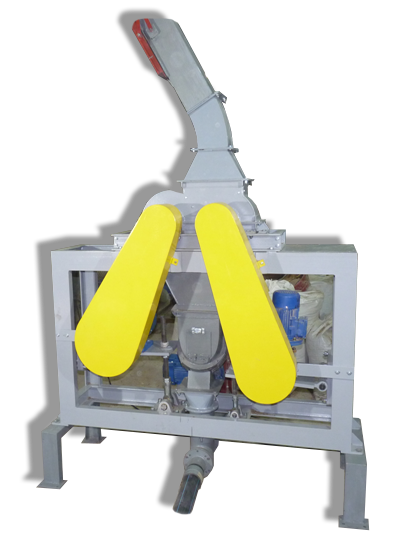

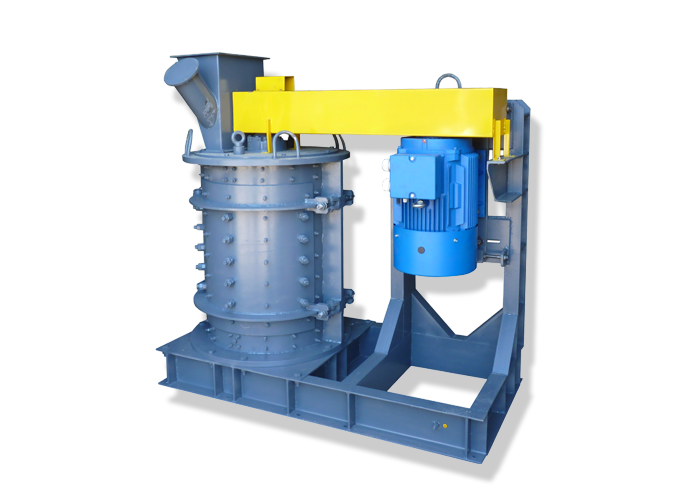

Waste wood after processing in a grinding mill.

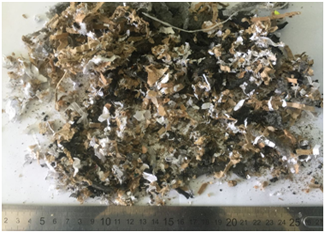

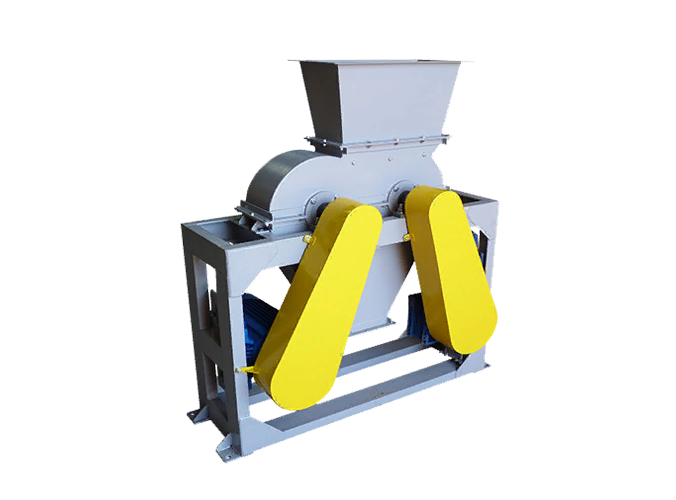

Waste wood after processing in a grinding mill and the shredder “Kesar” (Caesar) of medium grinding.

Waste wood after processing in the shredder “Kesar” (Caesar) of fine grinding.

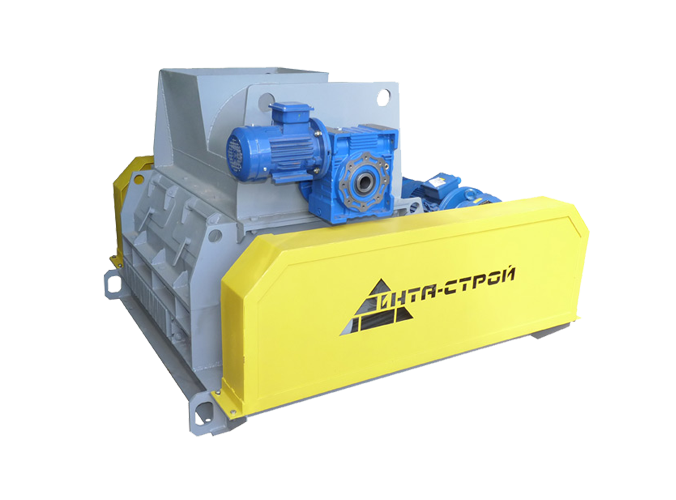

Original shuck of sunflower seed, after processing in the shredder “Kesar” (Caesar) of medium grinding, after processing in the shredder “Kesar” (Caesar) of fine grinding.

Household waste (cardboard, plastic bottles, porous rubber) after processing in the shredder “Kesar” (Caesar) of medium grinding

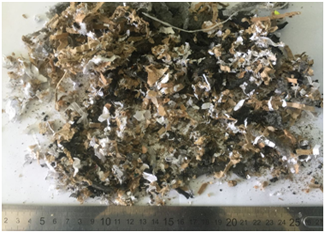

Screen sizing of waste wood with original fraction grade from 20 up to 100 mm (fig.5), with moisture content 56% after processing in a grinding mill and the shredder “Kesar” (Caesar)

|

Screen sizing of waste wood.

|

|

Mesh aperture, mm

|

After grinding mill, %

|

After grinding mill and the shredder “Kesar” (Caesar) of medium grinding, %

|

After grinding mill and the shredder “Kesar” (Caesar) of fine grinding, %

|

|

10

|

10

|

2

|

0

|

|

5

|

23

|

24

|

5

|

|

3

|

14

|

18

|

20

|

|

2

|

15

|

15

|

23

|

|

1

|

17

|

17

|

30

|

|

<1

|

21

|

24

|

22

|

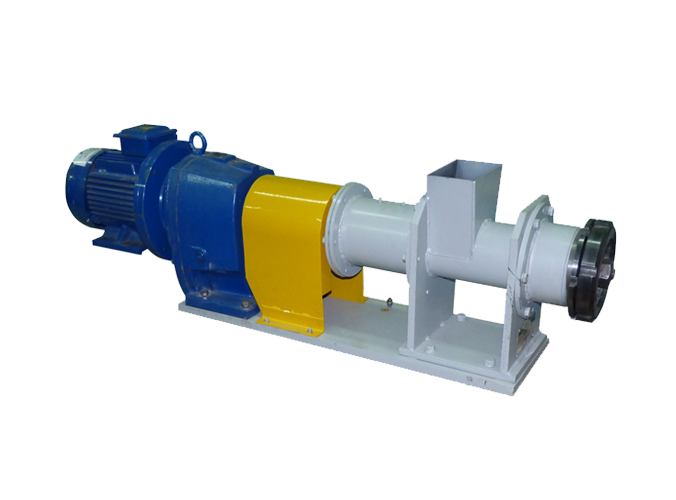

Screen sizing of original shuck of sunflower seed and after processing in the shredder “Kesar” (Caesar) of fine grinding, with moisture content 49%.

|

Screen sizing of shuck of sunflower seed.

|

|

Mesh aperture, mm

|

Original raw material, %.

|

After the shredder “Kesar” (Caesar) of fine grinding, %

|

|

10

|

10

|

0

|

|

6

|

53

|

1,6

|

|

5

|

23

|

23

|

|

3

|

9

|

23

|

|

2

|

6

|

26

|

|

1

|

3

|

18

|

|

<1

|

6

|

8

|

Order

Order